The application of precision casting in the field of pumps and valves

Products in the pump and valve field are mostly shaped parts, and have high sealing and pressure resistance requirements, so they are more suitable for stainless steel precision casting technology. Pump and valve precision casting is a precision casting process used to manufacture fluid control equipment components such as pumps and valves. It achieves high-precision control of component size, shape, and compressive performance by precisely controlling parameters such as materials, temperature, and pressure during the casting process, thus meeting the requirements of the pump and valve industry for high-quality and high reliability components.

Our achievements in the field of pumps and valves

We have been cooperating with many well-known valve companies internationally since 1998 to supply casting blanks. For example: various valve bodies (ball valves, diaphragm valves, angle valves, three-way valves, etc.), pump bodies, valve covers, pipe fittings, clamps, valve plates, pressure blocks, intermediate blocks, brackets, etc. We have PED qualification. ERP and MES systems provide comprehensive control over quality and delivery time. A certain amount of safety stock can be prepared for long-term products. Meet customers' strict requirements for quality and delivery time.

Our capabilities in the field of pumps and valves

1. Accuracy - The dimensional accuracy can reach CT4-CT6 level (GB/T 6414-1999), and the surface roughness Ra value can reach 1.6-6.3 μ m, which can meet the assembly requirements without or with only a small amount of machining. -Capable of forming complex structures (such as internal flow channels, multi curved shells, etc.), avoiding the limitations of traditional processing techniques.

2. Material - Stainless steel (such as 304, 316, 316) can be used L、1.4435/1.4408/1.4409、1.4308/1.4301、1.4404、CF3M、CF8M、CF3、CF8、CE3MN、 )Various materials such as carbon steel, alloy steel (such as chromium molybdenum steel), nickel based alloys, duplex steel, etc., meet the requirements of different working conditions such as corrosion resistance, high temperature resistance, and high pressure.

3. Production efficiency - Suitable for mass production, especially for parts with complex shapes and difficult cutting, it can significantly shorten the production cycle and reduce costs.

4. Performance - The casting structure is dense, and the mechanical properties (such as strength and toughness) are close to or reach the level of forgings (such as our precision cast butterfly valve plate replacing forged butterfly valve plate), which can withstand harsh working conditions (such as high-pressure fluids, corrosion, etc.).

Parameter

| Category |

Parameters |

| Casting Materials |

Common materials: Carbon steel, stainless steel, alloy |

|

Material weight range: 0.003 kg - 110 kg |

|

| Casting Dimensions |

Maximum casting size: Ø600mmX800mm |

|

Minimum casting size: 5 mm x 5 mm x 5 mm |

|

|

Casting wall thickness: 1 mm - 20 mm |

|

| Casting Precision |

Dimensional tolerance: ±0.05 mm - ±0.2 mm (depending on casting size) |

|

Surface roughness: Ra 3.2 µm -6.3 µm |

|

| Production Capacity |

Annual output: 600 tons |

|

Maximum single piece weight: 110 kg |

|

|

Minimum single piece weight: 3 grams |

|

|

Mold materials: Wax molds, ceramic molds |

|

| Casting Process |

Mold types: Precision wax mold casting |

|

Pouring methods: Gravity casting, vacuum casting |

|

| Heat Treatment Capability |

Heat treatment processes: Normalizing, annealing, quenching, tempering |

|

Treatment furnace temperature range: 600℃ - 1100℃ |

|

| Post-Processing |

Surface treatment: Polishing, sandblasting, machining, painting, hot-dip galvanizing, powder coating |

Our core process flow

1. Mold Design and Manufacturing - Use CAD/CAM technology to design molds, and use precision machining (such as CNC milling, electrical discharge machining) or 3D printing (such as SLS, SLA) to make molds, ensuring mold accuracy.

2. Wax mold making - Heat and melt medium temperature wax, press it into the mold cavity, and cool it to form a wax mold. -Repair and assemble the wax mold (such as welding the wax mold gate system) to form a wax mold assembly.

3. Shell preparation - coating refractory materials: immerse the wax mold group into the surface coating (such as silica sol+320 mesh zircon powder), then sprinkle zircon sand, dry to form the first layer of shell; Repeat multi-layer coating (usually using silica sol, mullite powder, and quartz sand for the back layer coating) until the thickness of the shell reaches 3-5mm. - Dewaxing: Place the shell in steam or hot water to melt the wax mold and form a hollow refractory shell. -Baking: The shell is baked at high temperatures (such as 850-1000 ℃) to remove residual wax and moisture, improve the strength and breathability of the shell.

4. Smelting and pouring - using an electric arc furnace to melt molten metal, ensuring the purity of the metal liquid. -Pour high-temperature metal liquid into the baked shell, and control the pouring temperature (such as stainless steel at about 1550-1650 ℃), pouring speed, and pouring method according to the material properties.

5. Cooling and Shedding - The metal liquid is slowly cooled in the mold shell (air cooling, air cooling, or water cooling can be used) to form castings. -The rough castings are obtained by cleaning the shell with a large shot blasting machine, cutting and grinding the gate.

6. Subsequent treatment - heat treatment: such as annealing, normalizing, quenching+tempering, to improve the mechanical properties of castings. -Surface treatment: Sandblasting, precision shot blasting to remove oxide skin, acid pickling passivation, electrolytic polishing or chemical plating to improve surface smoothness. -Testing: Dimensions and internal quality are inspected through methods such as coordinate measuring machine (CMM), penetration testing (PT), ultrasonic testing (UT), etc.

Main application areas

1. Industrial pump valves - valve bodies, valve covers, impellers, seals and other components for centrifugal pumps, reciprocating pumps, ball valves, globe valves, gate valves, etc. -The application scenarios include chemical fluids, power, metallurgy, water treatment and other industries, which need to meet high pressure, high temperature, corrosion and other working conditions.

2. Special pump valves - fuel pumps and hydraulic valves for aerospace applications; Corrosion resistant valves for nuclear power plants; High pressure pumps and valves used in deep-sea equipment require extremely high reliability for castings.

3. Civil and general equipment - air conditioning compressor components, fluid control components for medical devices, food grade pump valves (must meet hygiene standards), etc.

Key technical difficulties

1. Complex channel forming - The shape of the internal channel of the pump valve directly affects fluid efficiency, and it is necessary to control the precision of the mold and optimize the permeability of the shell to avoid defects such as insufficient filling and porosity.

2. Material segregation control - High alloy materials (such as duplex stainless steel) are prone to component segregation during solidification, which needs to be reduced through melting processes (such as rapid solidification) and pouring temperature control.

3. Deformation and crack prevention - Stress concentration is prone to occur during the cooling process of complex structural castings. Deformation and cracks can be reduced by optimizing the sprue and riser system, adopting sequential or simultaneous solidification processes, and increasing process bars.

Instant inquiry

Products in the pump and valve field are mostly shaped parts, and have high sealing and pressure resistance requirements, so they are more suitable for stainless steel precision casting technology.

Technological Process

Investment casting is a manufacturing process in which a liquid material is poured into a ceramic mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is the casting, which is broken away from the ceramic mold to complete the process. The steps within the investment casting process are as follows:

01

Wax Injection

Injection of medium-temperature wax (60-65°C) into metal molds under 0.5-0.7 MPa pressure, with a dwell time of 20-30 seconds.

02

Wax Pattern Trimming

Removal of flash from wax pattern parting lines with precision ±0.1 mm, using hot knives (70-90°C)

03

Cluster Assembly

Welding wax patterns to a central sprue, with cluster weight ≤15 kg, pattern spacing ≥8 mm, and pouring angle of 25-30°.

04

Primary Coating

Silica sol (SiO₂ 20%) + zircon flour (ZrO₂ 80%), 320-mesh,viscosity 42-45 seconds (#4 Zahn cup), coating thickness 0.3-0.5 mm.

05

Backup

Quartz sand, 80~120-mesh 、30~60-mesh 、16~30-mesh chamotte sand stuccoing, total shell thickness 6-8 mm, green strength ≥4 MPa.

06

Dewaxing

High-pressure steam dewaxing (0.6-0.8 MPa, 150-170°C), residual wax ≤0.3%, shell breakage rate <0.5%.

07

Pouring

Gravity casting with preheated molds (1000-1200°C), pouring rate 0.8-1.2 kg/s, solidification cooling rate 50-100°C/min.

08

Shot Blasting & Clear

Shell removal using Φ0.5 mm cast steel shot at 0.4-0.6 MPa,It only takes 20 minutes to remove the casting shell

09

Cutting

Grinding wheel gate removal with ≤1.5 mm allowance, cutting temperature <200°C (to prevent microstructural degradation).

10

Gate Grinding

Resin-bonded grinding wheel (120 grit) for gate finishing, residual gate height ≤0.3 mm, transition radius R≥0.5 mm.

11

TIG Welding & Finishing

Argon shielding (purity ≥99.999%), ER316L filler wire, post-weld grinding to Ra ≤6.3 μm.

12

Final Inspection

PT (penetrant testing), RT (X-ray), full dimensional inspection (CT6-CT8 per ISO 8062), compliant with AMS 2175/ISO 4990.

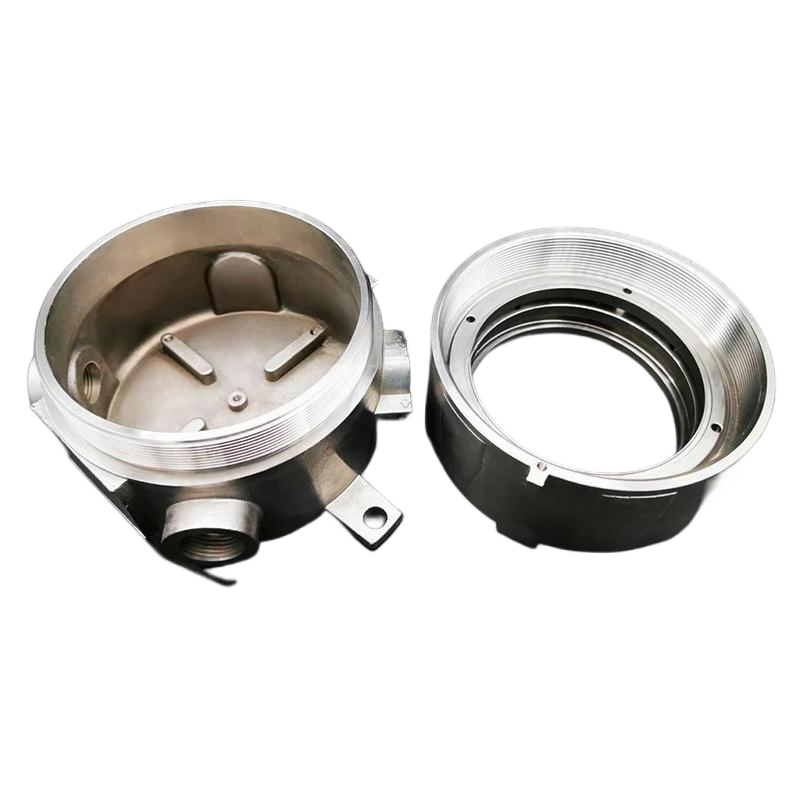

Some of our product catalogs

Investment casting is a manufacturing process in which a liquid material is poured into a ceramic mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is the casting, which is broken away from the ceramic mold to complete the process. The steps within the investment casting process are as follows:

Product brochure download

Pump and valve castings precision casting

Pump and valve castings precision casting

Diaphragm valve

Centrifuge

Pump and valve castings precision casting

Pump and valve castings precision casting

Handle switch

Vane wheel

Pump and valve castings precision casting

Pump and valve castings precision casting

Pump and valve castings precision casting

Vane wheel

Pump and valve castings precision casting

Butterfly valve plate

Diaphragm valve

Valve deck

Pump and valve castings precision casting

Pump and valve castings precision casting

Pump and valve castings precision casting

Pump and valve castings precision casting