The application of dense casting in the field of textile machinery

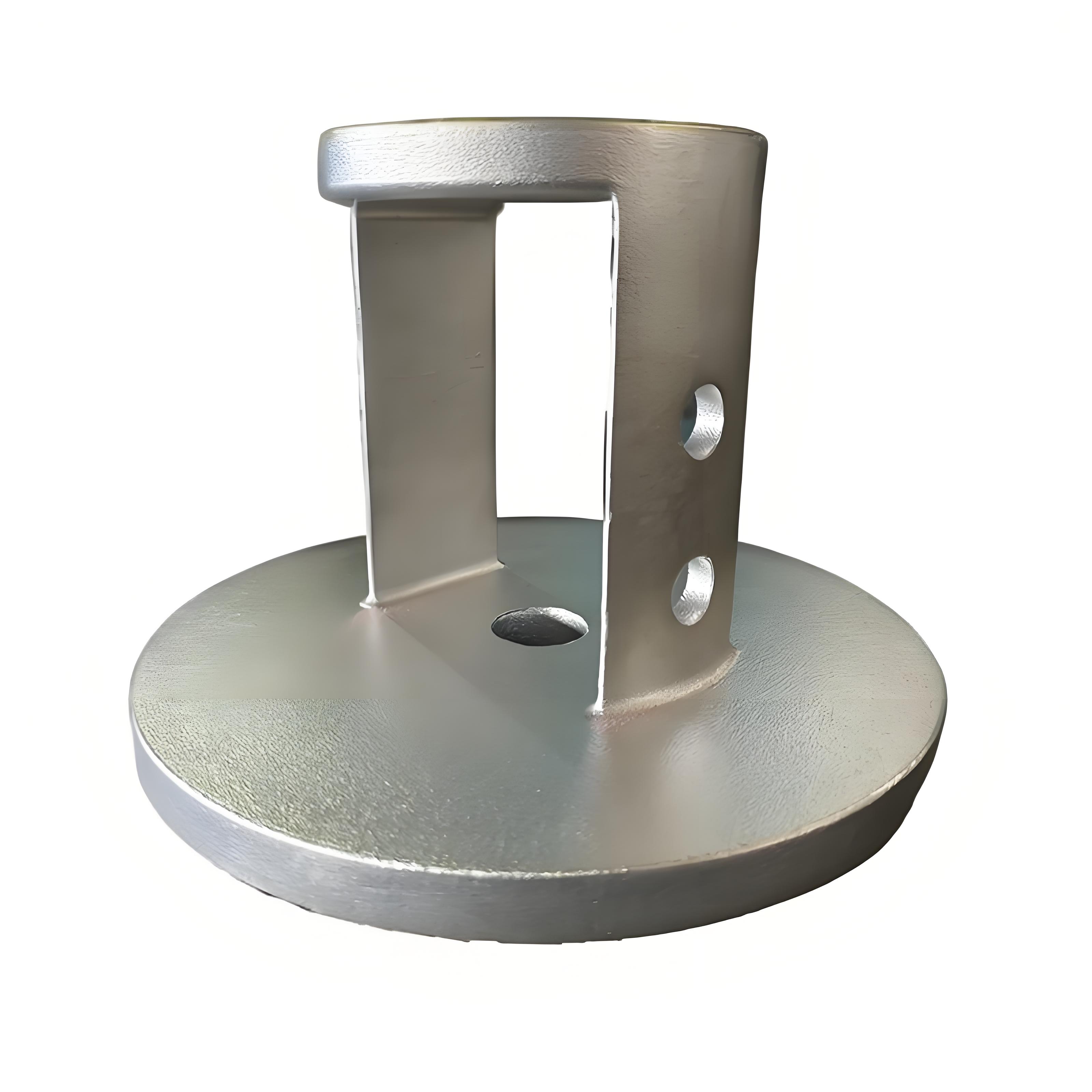

The field of textile machinery is characterized by high precision, high surface roughness requirements, wear resistance, complex structure, and miniaturization. Many key components require the use of stainless steel precision casting technology, namely medium temperature wax silica sol casting technology, to complete.

Our achievements in the field of textile machinery

We have been cooperating with internationally renowned enterprises in the field of textile machinery for many years, providing precision casting blanks, finished products, and finished assembly parts. Due to the variety of surface treatment methods available to customers, in order to better serve them, I have prepared sufficient inventory of some key components for urgent use by customers.

Our capabilities in the textile field

1. The dimensional tolerance of parts usually needs to be controlled within ± 0.05~± 0.2mm. For key components such as spinning machine spindles and roller bearings, the fitting clearance error should be ≤ 0.01mm to ensure the stability of equipment operation and the quality of textiles. Surface roughness: Ra value is often required to be ≤ 3.2 μ m, and can even reach Ra ≤ 0.8 μ m (such as combing machine needle seat, yarn guide, etc.), reducing fiber friction damage and improving yarn uniformity.

2. Diversified material properties: Cast iron (such as HT250, QT600-3) is used for components such as frames and gearboxes that withstand alternating loads, with a hardness of ≥ HB200; Stainless steel (such as 304, 316) used for parts that come into contact with synthetic oils or humid environments (such as dyeing machine guide rollers) must pass a salt spray test (≥ 500 hours without corrosion).

3. Complex and miniaturized structure, complex inner cavity and thin-walled structure: For example, the airflow nozzle of a jet loom has an internal channel diameter of only 1-3mm, which needs to be formed in one go through precision wax loss casting to avoid the problems of high channel roughness and airflow disorder caused by traditional machining. Miniature parts: Needle base of knitting machine (size ≤ 10mm × 10mm), requiring no porosity or shrinkage in the casting, and using pressure casting or metal mold casting to increase density.

Parameter

| Category |

Parameters |

| Casting Materials |

Common materials: Carbon steel, stainless steel, alloy |

|

Material weight range: 0.003 kg - 110 kg |

|

| Casting Dimensions |

Maximum casting size: Ø600mmX800mm |

|

Minimum casting size: 5 mm x 5 mm x 5 mm |

|

|

Casting wall thickness: 1 mm - 20 mm |

|

| Casting Precision |

Dimensional tolerance: ±0.05 mm - ±0.2 mm (depending on casting size) |

|

Surface roughness: Ra 3.2 µm -6.3 µm |

|

| Production Capacity |

Annual output: 600 tons |

|

Maximum single piece weight: 110 kg |

|

|

Minimum single piece weight: 3 grams |

|

|

Mold materials: Wax molds, ceramic molds |

|

| Casting Process |

Mold types: Precision wax mold casting |

|

Pouring methods: Gravity casting, vacuum casting |

|

| Heat Treatment Capability |

Heat treatment processes: Normalizing, annealing, quenching, tempering |

|

Treatment furnace temperature range: 600℃ - 1100℃ |

|

| Post-Processing |

Surface treatment: Polishing, sandblasting, machining, painting, hot-dip galvanizing, powder coating |

Instant inquiry

Products in the pump and valve field are mostly shaped parts, and have high sealing and pressure resistance requirements, so they are more suitable for stainless steel precision casting technology.

Technological Process

Investment casting is a manufacturing process in which a liquid material is poured into a ceramic mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is the casting, which is broken away from the ceramic mold to complete the process. The steps within the investment casting process are as follows:

01

Wax Injection

Injection of medium-temperature wax (60-65°C) into metal molds under 0.5-0.7 MPa pressure, with a dwell time of 20-30 seconds.

02

Wax Pattern Trimming

Removal of flash from wax pattern parting lines with precision ±0.1 mm, using hot knives (70-90°C)

03

Cluster Assembly

Welding wax patterns to a central sprue, with cluster weight ≤15 kg, pattern spacing ≥8 mm, and pouring angle of 25-30°.

04

Primary Coating

Silica sol (SiO₂ 20%) + zircon flour (ZrO₂ 80%), 320-mesh,viscosity 42-45 seconds (#4 Zahn cup), coating thickness 0.3-0.5 mm.

05

Backup

Quartz sand, 80~120-mesh 、30~60-mesh 、16~30-mesh chamotte sand stuccoing, total shell thickness 6-8 mm, green strength ≥4 MPa.

06

Dewaxing

High-pressure steam dewaxing (0.6-0.8 MPa, 150-170°C), residual wax ≤0.3%, shell breakage rate <0.5%.

07

Pouring

Gravity casting with preheated molds (1000-1200°C), pouring rate 0.8-1.2 kg/s, solidification cooling rate 50-100°C/min.

08

Shot Blasting & Clear

Shell removal using Φ0.5 mm cast steel shot at 0.4-0.6 MPa,It only takes 20 minutes to remove the casting shell

09

Cutting

Grinding wheel gate removal with ≤1.5 mm allowance, cutting temperature <200°C (to prevent microstructural degradation).

10

Gate Grinding

Resin-bonded grinding wheel (120 grit) for gate finishing, residual gate height ≤0.3 mm, transition radius R≥0.5 mm.

11

TIG Welding & Finishing

Argon shielding (purity ≥99.999%), ER316L filler wire, post-weld grinding to Ra ≤6.3 μm.

12

Final Inspection

PT (penetrant testing), RT (X-ray), full dimensional inspection (CT6-CT8 per ISO 8062), compliant with AMS 2175/ISO 4990.

Some of our product catalogs

Investment casting is a manufacturing process in which a liquid material is poured into a ceramic mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is the casting, which is broken away from the ceramic mold to complete the process. The steps within the investment casting process are as follows:

Product brochure download

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting

Textile machinery precision casting